Oil & Gas

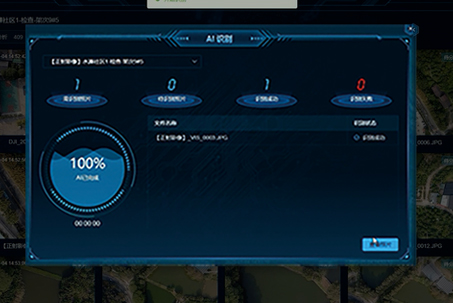

In the oil and gas industry, drones have become an indispensable and powerful tool. Leveraging the highly advanced drone intelligent inspection system, a multitude of sophisticated capabilities are actualized. The AI – based detection enables accurate identification of potential issues, while the intelligent analysis further processes the collected data to extract valuable insights. With real – time abnormal alerts, immediate attention can be directed towards any incipient issues, ensuring prompt response and mitigation. The digitalized operation and maintenance framework streamlines and optimizes the overall management and upkeep procedures.

Drones enhance the safety and efficiency of operations in the oil and gas industry, providing a reliable solution for continuous monitoring and effective management of various facilities and processes.

Main Challenges in Oil & Gas Inspections

Harsh and Hazardous Environments

The oil and gas facilities are often located in remote, desolate, and extreme environments such as deserts, swamps, or offshore areas. These locations pose significant challenges for traditional inspection methods. For example, in desert regions, the scorching heat and sandstorms can damage inspection equipment and endanger the safety of inspection personnel. In offshore platforms, strong winds, high waves, and corrosive sea air can cause rapid wear and tear of equipment and make it difficult to access certain areas for inspection.

High-cost and Time-consuming Manual Inspections

Manual inspections in the oil and gas industry require a large amount of manpower and time. Skilled technicians need to travel to various locations of the facilities, which may involve complex procedures such as obtaining permits and arranging transportation. Moreover, the inspection process itself is labor – intensive. For instance, inspecting a long pipeline network may take weeks or even months, during which the technicians have to walk along the pipeline, check for leaks, corrosion, and other issues. This not only incurs high labor costs but also may lead to production disruptions due to the long inspection cycle.

Inaccuracy and Inefficiency of Traditional Detection Methods

Traditional inspection techniques like visual inspection and simple sensor – based detection have limitations. Visual inspection is highly subjective and may miss small or hidden defects. Basic sensors may not provide comprehensive and accurate data. For example, detecting minor cracks in a storage tank or a subtle change in the pressure of a pipeline may be difficult with traditional methods. This can result in undetected problems that may escalate into major safety hazards or costly equipment failures over time.

Lack of Real – time Monitoring and Immediate Response Capability

Most traditional inspection systems do not offer real – time monitoring. There is a significant time lag between the occurrence of an issue and its discovery. This delay means that problems cannot be addressed immediately, increasing the risk of accidents and production losses. For example, a small leak in a gas pipeline may go unnoticed for hours or days until the next scheduled inspection, during which time the leak could potentially cause an explosion or environmental pollution.

Difficulty in Data Integration and Analysis

The data collected from different inspection sources and methods in the oil and gas industry is often heterogeneous and difficult to integrate. Different sensors, inspection tools, and reporting systems may use different formats and protocols. This makes it challenging to conduct comprehensive data analysis and draw meaningful conclusions. For instance, data from a corrosion sensor and a flow meter may not be easily combined to assess the overall health of a pipeline system, preventing the optimization of maintenance schedules and resource allocation.

What Can Drones Do in Inspections?

Pipeline Inspection

Drones equipped with high-resolution cameras and thermal imaging sensors can fly along pipelines to conduct comprehensive inspections. They can detect pipeline leaks, cracks, and abnormal temperature changes in a timely manner. For example, in a long-distance gas pipeline, drones can quickly identify potential safety hazards and provide accurate location information, enabling maintenance personnel to take timely measures and avoid serious accidents.

Wellsite Monitoring

In oil and gas wellsites, drones can monitor the operation status of drilling rigs, wellheads, and surrounding facilities. They can observe the working conditions of equipment, such as whether the drill bit is operating normally and whether there is any oil spill around the wellhead. This helps improve the safety and efficiency of wellsite operations and enables real-time monitoring and early warning of potential problems.

Storage Tank Inspection

Drones can hover over storage tanks to check the integrity of the tank body, including the detection of corrosion, deformation, and cracks. By using 3D mapping technology, they can create detailed models of storage tanks to accurately assess the condition of the tanks and plan maintenance and repair work.

Advantages of Drone Inspections

High Efficiency and Wide Coverage

Drones can cover a large area in a short time, which is much faster than traditional manual inspection methods. They can quickly inspect extensive pipeline networks, multiple wellsites, and large storage tank areas, saving a significant amount of time and manpower. For instance, a drone can complete the inspection of a several-kilometer-long pipeline in a few hours, while manual inspection may take days.

Enhanced Safety

In the hazardous environment of the oil and gas industry, drones can replace workers to perform dangerous inspection tasks. They can access areas that are difficult or dangerous for humans to reach, such as high-altitude pipelines and wellsites with potential gas leaks. This reduces the risk of accidents and ensures the safety of personnel.

Accurate Data Collection

The advanced sensors carried by drones can collect a large amount of accurate data. High-resolution cameras can capture clear images of equipment and facilities, and thermal imaging sensors can detect hidden problems. These data provide a reliable basis for equipment maintenance, performance evaluation, and decision-making in the oil and gas industry.

Cost-Effective

Although the initial investment in drones and related equipment is required, in the long run, it can significantly reduce costs. By improving inspection efficiency, reducing the need for manual labor, and preventing major accidents and equipment failures, it helps save a considerable amount of maintenance and operation costs for oil and gas enterprises.

MECHO's Drone System to Inspection

C60 Industrial Drone

G900 Drone Dock

Drone Cloud Platform

Have more questions? Need a price quote or want to become a dealer?