Drone Electric Propulsion System E6

Engineered for precision, reliability, and adaptability, MECHO’s drone propulsion systems redefine performance across commercial, agricultural, and enterprise-grade UAV applications. Our integrated solution E6 propulsion system combine cutting-edge technology with user-centric design to deliver seamless flight experiences tailored to diverse operational needs.

High-Thrust Propulsion System

The E6 Propulsion System is a high-thrust integrated solution engineered for drone platforms requiring 3kg to 6kg of thrust per rotor. Built for precision and reliability, it leverages FOC vector control and dual throttle redundancy, paired with a modular design, epoxy-sealed construction, intelligent data monitoring, fault logging, and IPX6 water resistance. Ideal for commercial and agricultural drones, it balances performance, durability, and ease of integration for enterprise-grade applications.

Powerful Thrust, Effortless Flight

Designed to deliver 6 kg of thrust per rotor as the recommended maximum, the system achieves an efficiency of 7 g/W—optimizing power output for heavy payloads. Its robust power redundancy ensures smooth, stable flight even under load, extending flight endurance and boosting operational efficiency for mission-critical applications.

Premium Propeller Design

Engineered with a high-pitch profile and advanced aerodynamics, these propellers deliver robust thrust while maximizing energy efficiency—ideal for demanding drone operations. Crafted from carbon fiber-reinforced nylon composite, they resist corrosion and require minimal maintenance, ensuring long-lasting performance in harsh environments.

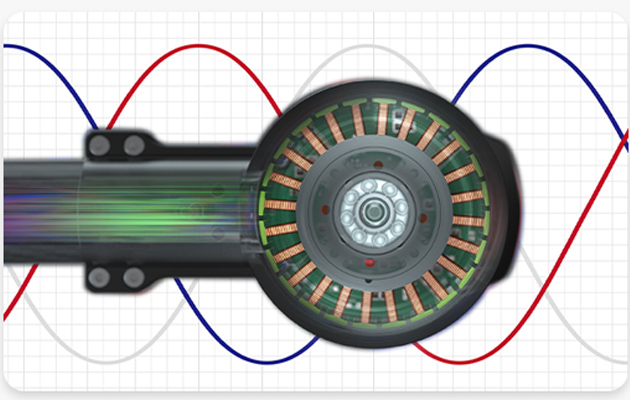

FOC ESC for Precise Motor Control

The electronic speed controller (ESC) employs advanced FOC (Field-Oriented Control) vector technology, enabling sensitive, efficient, low-noise operation with exceptional stability—critical for precise drone maneuvering and responsive flight control.

Modualar Design for Plug-and-Play Integration

This fully integrated propulsion system streamlines setup with zero component assembly required—simply mount it onto the drone arm. Engineered for hassle-free deployment, its high-density integration enables rapid installation, making it ideal for time-sensitive applications where efficiency and convenience are critical.

Wide Voltage Compatibility for Diverse Applications

The E6 system supports a maximum 63V operating voltage, seamlessly integrating with 12–14S LiHV batteries. Its broad voltage platform compatibility ensures reliable performance across varied operational conditions, making it an ideal choice for drones requiring adaptability in power supply configurations.

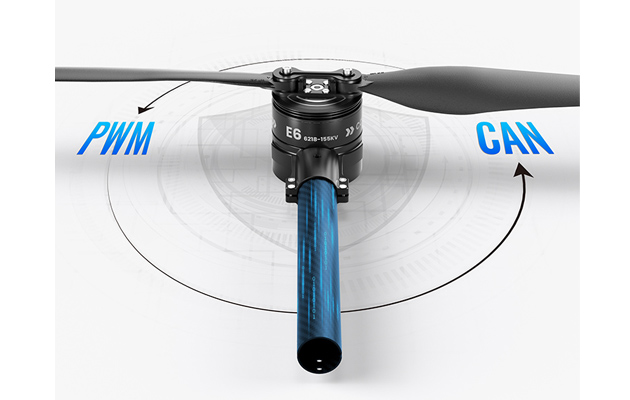

PWM & CAN Dual Throttle Redundancy

Featuring PWM and CAN dual throttle redundancy, the system enables precise, linear throttle control for seamless maneuvering. The dual-channel backup design ensures flight safety by automatically switching to the secondary control path in abnormal conditions, guaranteeing uninterrupted, worry-free operation even in critical scenarios.

Rapid Perception Feedback and Fault Storage

The ESC autonomously stores its operational data. The optional CAN LINK module offers a comprehensive suite of functions, including firmware upgrades, real – time data monitoring, historical data queries, fault storage data analysis, and ESC parameter adjustment. Leveraging the CAN communication protocol, it provides rapid perception feedback, enabling real – time system status detection and pre-emptive risk mitigation.

People Who Viewed This Also Be interested in

More Information About Drone Propulsion System

Yes, but ensure compatibility:

Voltage Range: ESCs must support the battery’s cell count (e.g., 6S ESC for a 22.2V battery).

Signal Protocols: Most ESCs use PWM, but advanced systems may require CAN/SBUS—verify flight controller compatibility.

Thrust Matching: Pair motors with propellers within their recommended thrust range (check manufacturer specs).

Brushed Motors: Cheaper, simpler, but less efficient, shorter lifespan (best for small toy drones).

Brushless Motors: Higher efficiency, longer life, and precise control—dominant in commercial/industrial drones (rated by KV value: higher KV = faster RPM for smaller props).

Cold Weather: Batteries lose capacity; pre-warm LiPo batteries to 20–25°C for optimal discharge.

Hot Weather: Motors/ESCs may overheat—add heat sinks or adjust flight profiles for shorter, slower missions.

Humidity: Use waterproof coatings or IP-rated components to prevent corrosion.