Photovoltaic Industry

The application of drones in the photovoltaic industry has brought significant advancements. Drones are extensively used for solar panel inspection. Equipped with high-resolution cameras and thermal imaging sensors, they can quickly and accurately detect faults such as cracks, hot spots, and dirt accumulation on the panels. This enables timely maintenance and repair, maximizing the power generation efficiency of photovoltaic power plants. They can cover large areas of solar farms in a short time, which is much more efficient than traditional manual inspection methods. Moreover, drones assist in site surveying and mapping for new photovoltaic projects. They collect detailed geographical and topographical data, helping engineers to design more optimized layouts and installations. In conclusion, the utilization of drones in the photovoltaic industry has enhanced operational efficiency, reduced costs, and improved the overall performance and reliability of photovoltaic systems.

Main Challenges of Photovoltaic Industry Inspections

Labor – Intensive and Time – Consuming

Traditional photovoltaic inspection heavily relies on manual labor. Inspectors need to traverse large areas of solar farms on foot or by vehicle. For extensive photovoltaic power plants, this process can take a significant amount of time. Workers have to check each solar panel one by one, which is not only physically demanding but also highly inefficient. For example, in a large – scale solar power station with thousands of panels, it may take several days or even weeks to complete a single round of comprehensive inspection, delaying the detection and resolution of potential issues.

Limited Detection Accuracy

Manual inspection often depends on the naked eye or simple tools. Inspectors may miss some subtle faults or early signs of problems. Cracks on solar panels, loose connections, or slight changes in performance that are not easily observable with the naked eye can go unnoticed. Thermal issues such as hot spots, which are crucial for panel health and efficiency, are difficult to accurately detect without advanced equipment. This limited accuracy can lead to undetected faults escalating into more serious problems, reducing the overall power generation efficiency and lifespan of the photovoltaic system.

Hazardous Working Conditions

Inspectors working in photovoltaic plants face various hazardous conditions. They have to work under direct sunlight for long periods, increasing the risk of heatstroke and sunburn. In some cases, they need to climb onto rooftops or use elevated platforms to access panels, posing a significant risk of falls and accidents. Moreover, in areas with extreme weather conditions like strong winds or heavy rain, the inspection work becomes even more dangerous and may have to be postponed, further affecting the regularity and timeliness of inspections.

Data Collection and Analysis Difficulties

Traditional inspection methods make it challenging to collect and analyze comprehensive data. Manual records are prone to errors and are often incomplete. It is difficult to establish a detailed and accurate database of panel conditions over time. Without proper data analysis tools and systems, it is impossible to identify trends or predict potential failures. This lack of data – driven insights hinders proactive maintenance strategies and optimal operation of the photovoltaic facility.

What Can Drones Do in Photovoltaic Industry Inspections?

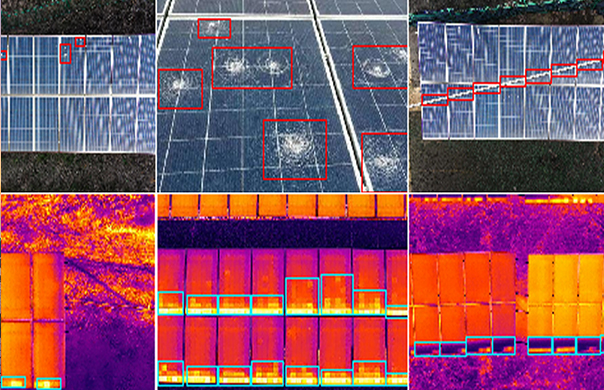

Inspection of Solar Panels

Drones equipped with high-resolution cameras can conduct detailed visual inspections of solar panels. They can capture clear images of the surface of each panel to check for visible damages such as cracks, scratches, and discoloration. By flying over the photovoltaic array in a systematic pattern, the drone can cover a large area quickly and ensure that no panel is overlooked. The images obtained can be analyzed later to identify any anomalies and determine the extent of the damage, allowing for timely repair or replacement.

Thermal Imaging for Fault Detection

One of the crucial tasks of drone inspection in the photovoltaic industry is thermal imaging. Drones with thermal cameras can detect temperature differences across the solar panels. Hot spots, which are areas of abnormally high temperature, often indicate potential faults such as defective cells, poor electrical connections, or shading issues. The drone can create a thermal map of the entire solar farm, highlighting the hot spots and providing precise location information. This enables maintenance crews to target the specific panels that require attention and address the issues before they lead to significant power losses or permanent damage to the panels.

Monitoring of Array Alignment and Structure

Drones can also assess the alignment and overall structure of the solar panel array. They can check if the panels are properly installed and oriented to receive maximum sunlight. Any misalignment or tilting of panels can affect the efficiency of power generation. Additionally, the drone can inspect the supporting structures for signs of damage, such as corrosion, cracks, or loose bolts. By identifying these structural issues early, the safety and stability of the photovoltaic installation can be maintained, and potential collapses or accidents can be prevented.

Advantages of Drone Inspections in Photovoltaic Industry

High Efficiency and Wide Coverage

Drones can cover large areas of photovoltaic power plants in a relatively short time. They can quickly navigate through the solar panel arrays, reaching areas that are difficult or time-consuming for human inspectors to access. For example, in a sprawling solar farm spanning hundreds of acres, a drone can complete an aerial inspection in a fraction of the time it would take a team of workers on foot or in vehicles. This enables more frequent and comprehensive inspections, ensuring that potential issues are detected promptly.

High – Precision Detection Capabilities

Equipped with advanced imaging technologies such as high-resolution cameras and thermal sensors, drones can detect even the slightest faults and abnormalities. The high-resolution visual cameras can capture detailed images of the solar panels, revealing surface defects like tiny cracks or scratches. The thermal sensors can accurately identify hot spots, which are indicative of internal panel malfunctions or connection problems. This level of precision far exceeds what can be achieved with traditional manual inspection methods, allowing for early intervention and minimizing the impact on power generation efficiency.

Enhanced Safety

Drone inspections eliminate the need for human inspectors to work at heights or in hazardous environments. In photovoltaic installations, inspectors may have to climb rooftops or use scaffolding to access panels, which poses a significant risk of falls and injuries. With drones, the inspection process can be carried out remotely, reducing the exposure of workers to potential accidents. Additionally, drones can operate in adverse weather conditions, such as strong winds or extreme temperatures, where it would be dangerous for humans to conduct inspections.

Data-Driven Insights and Analysis

Drones collect vast amounts of data during inspections, including visual images and thermal data. This data can be processed and analyzed using specialized software to generate valuable insights. Trend analysis can be performed to predict potential failures based on the progression of faults over time. The data can also be used to optimize the maintenance schedule, allocating resources more efficiently. For instance, by analyzing the frequency and location of faults, maintenance teams can prioritize their efforts and focus on the areas that require immediate attention, thereby reducing downtime and increasing the overall productivity of the photovoltaic system.

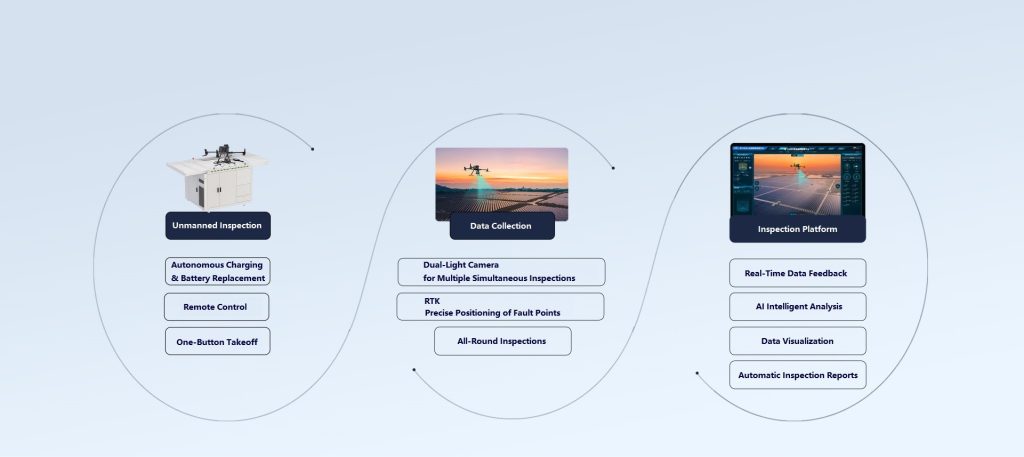

MECHO's Drone System for Photovoltaic Industry Inspections

C60 Industrial Drone

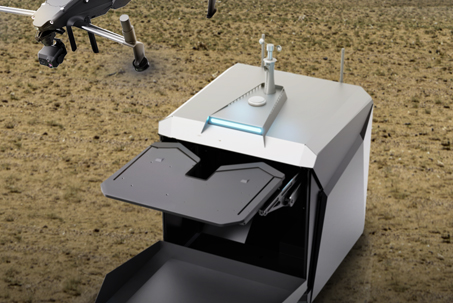

M710 Drone Dock

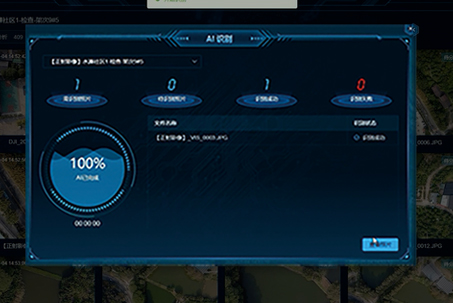

Drone Cloud Platform

Have more questions? Need a price quote or want to become a dealer?